Changing Grease

Ideally, the best procedure to follow when changing grease brands is to completely remove all old grease before new grease is added. This is usually done, for example, when automotive wheel bearings are repacked with grease. In some pieces of equipment, such as electric motors, the grease-lubricated bearings are not designed to be relubricated, as the grease lubrication life and the bearing life are about the same. In these cases, the bearing is replaced with a new pregreased bearing and the old one is dicarded.

Compatible Grease

In the majority of cases, however, grease lubrication is performed periodically by adding grease to the existing grease in a piece of equipment. During a change from one grease brand to another, when complete removal of the old grease is impractical, much of the old grease may be removed by purging with new grease. This can be done initially and/or progressively by temporarily increasing both the application intervals and the quantity of grease applied. Purging old, hard, contaminated grease with new grease is advisable even if grease brands are not changed to ensure that all parts of the equipment are actually receiving new grease. Sometimes, small openings in the grease lubricated area become clogged with contaminated or old grease and normal relubrication is not sufficient to distribute fresh lubricant to all parts of the equipment.

Afer thorough purging with the new grease, the equipment should be monitored for signs of possible incompatibility such as grease leakage, abnormally high operating temperatures (if equipment is not overpacked with grease), or noise.

Incompatible Grease

Incompatibility is a factor only during changeover or conversion and, therefore, is always a temporary matter. Good sound recommendations can usually overcome or minimize any field difficulties during conversion. If circumstances warrant, selected equipment can be changed under close surveillance prior to plant-wide conversions. Also, laboratory bench tests can determine whether a compatibility problem exists. They are not, however, conclusive.

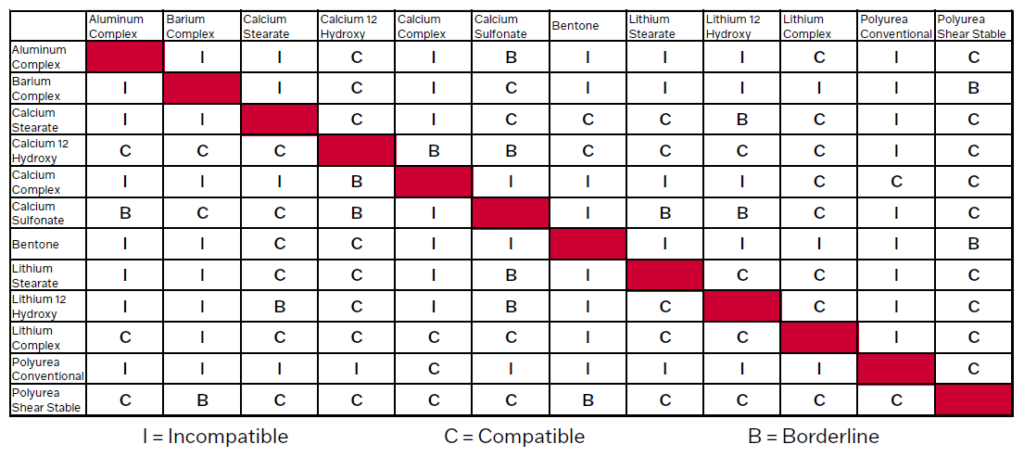

Grease Compatibility Chart

The following chart should only be used as a guideline for determining compatibility. For the purpose of changing products in the field, the compatibility of the greases in question should be determined by laboratory testing. Find a printable version here!

If you ever have any questions about what grease is right for you please call or text our Technical Specialist - Corey Foy at 780.238.6598.