Greasing is a crucial component of service maintenance, despite it not often being given the attention it deserves. Improper greasing practices can lead to a lack of lubrication in critical areas, leading to premature wear and failure. This blog aims to pinpoint some of these poor practices so you can keep your equipment in good condition. Here are the top 3 greasing mistakes for you to avoid in the field:

1. You’re not greasing enough (or you’re greasing too much).

The purpose of grease is to provide lubrication where you can’t use oil. The thickener in grease will hold the oil in place, and under pressure the oil will separate out ensuring there is a proper film thickness between the metal parts.

A lack of grease means that these metal parts will make contact, causing accelerated wear and premature failure. It is crucial that you keep up with your recommended greasing intervals to ensure that you always have lubrication.

That being said, it is crucial that you do not over-grease as well. Over-greasing can cause blown seals and overheating. Make sure to follow OEM recommendations for greasing amounts and frequency.

2. You didn’t check if you’re using the right grease, for the right application.

Not all grease is the same, so it is critical that you’re choosing the right grease for your purpose. A couple key points to note are:

- Thickener types:

- Complex vs Soap based greases: a complex will have better high temperature performance.

- Characteristics: Calcium Complex has good water resistance; Lithium Complex has good high temperature performance (barium for extremely high temperatures) and polyurea in electric motor bearing applications.

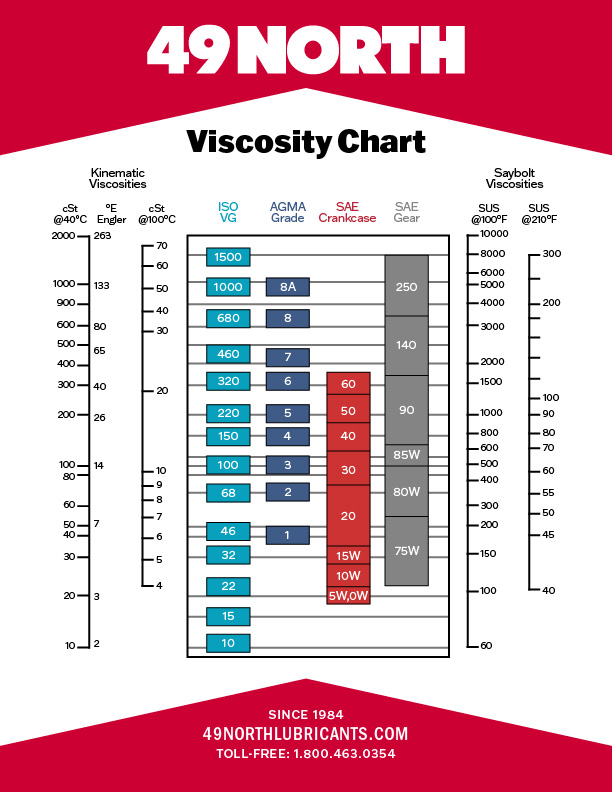

- Speed and Load: Typically, high speed/low load applications use higher NLGI grades and lower viscosity base oils, whereas low speed/high loads use lower NLGI grades and higher viscosity base oils.

- Extreme Pressure Additives: Some greases will use Sulphur Phosphorous EP additives, while others use molybdenum disulphide (moly) for extreme pressure protection. Moly is a solid additive which can be abrasive at high speeds, so it is important to make sure you are using it in the right application.

3. You didn’t check that the greases you’re mixing are compatible.

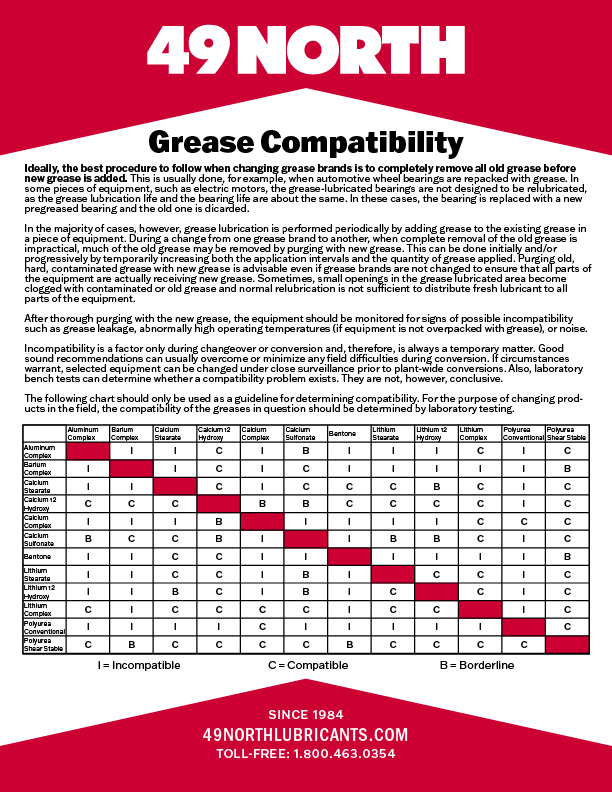

In the majority of cases, mixing incompatible grease will result in grease softening and running out. This will be due to the thickener type being incompatible with one another. The compatibility chart below gives an overview of most grease type’s performance with one another.

When changing greases, the best practice is to purge the old grease before operating your equipment. Not only does this ensure that fresh grease is in the system, but it will also decrease compatibility concerns as most of the old grease will be removed from the system.

Contact Us:

Avoid these 3 greasing mistakes, and your equipment will be running smoother in no time! For support in choosing the right grease for your application, and all other lubrication inquiries, please email info@49northlubricants.com or call 1-800-463-0354.